One way valve

Application

RVH and RV series safety valve is proportional to the pressure relief valve, when the pressure is increased, it is gradually open, they are given a rise in the pressure (cumulative) no capacity rating, and they do not press ASME or any other criteria to test. Some system applications require a safety valve to meet specific safety guidelines, so the system designers and users must determine when to apply these safety guidelines and whether these safety valves are in compliance with safety standards.

Operation

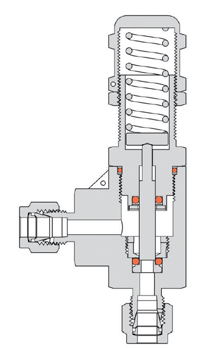

■ when the system pressure reaches the set pressure of the safety valve open, when the system pressure drops below the set pressure when closed.

■In the selection and installation of safety valve cover a desired set pressure spring, and the corresponding label affixed to the cap on.

■ for not use over a period of time in the initial unloading valve, pressure may be higher than the set pressure high.

■ set pressure and sealing pressure

■Set pressure is the first time when the upstream pressure of fluid outflow. At room temperature, the setting pressure of each valve can be repeated in the 5% range.

■Seal pressure is no flow of the upstream pressure, and then seal pressure is always below the set pressure

Test

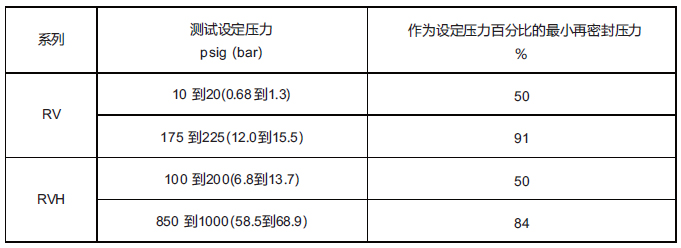

Each series of proportional unloading valve to go through setting performance and re sealing performance test.

RVH and RV series safety valve is proportional to the pressure relief valve, when the pressure is increased, it is gradually open, they are given a rise in the pressure (cumulative) no capacity rating, and they do not press ASME or any other criteria to test. Some system applications require a safety valve to meet specific safety guidelines, so the system designers and users must determine when to apply these safety guidelines and whether these safety valves are in compliance with safety standards.

Operation

■ when the system pressure reaches the set pressure of the safety valve open, when the system pressure drops below the set pressure when closed.

■In the selection and installation of safety valve cover a desired set pressure spring, and the corresponding label affixed to the cap on.

■ for not use over a period of time in the initial unloading valve, pressure may be higher than the set pressure high.

■ set pressure and sealing pressure

■Set pressure is the first time when the upstream pressure of fluid outflow. At room temperature, the setting pressure of each valve can be repeated in the 5% range.

■Seal pressure is no flow of the upstream pressure, and then seal pressure is always below the set pressure

Test

Each series of proportional unloading valve to go through setting performance and re sealing performance test.

|

| Back pressure ■ High pressure valve (RVH) Through the design of these high-pressure valve to minimize the impact of the system back pressure. ■ low pressure valve (RV) System back pressure will increase the set pressure valve. In order to compensate, multiply the back pressure by 0.8 and subtract from the desired set pressure. When the back pressure is equal to the atmospheric pressure, the application of the results to the preset valve. For example: the required set of pressure is 120 psig. system back pressure is 40 psig. Step 1 multiply the back pressure by 0.8. 40 X psig 0.8 = 32 psig. Step 2 minus the required set pressure. 120 psig - 32 psig = 88 psig. Step 3 the proportion of the unloading valve is set at 88 psig. |

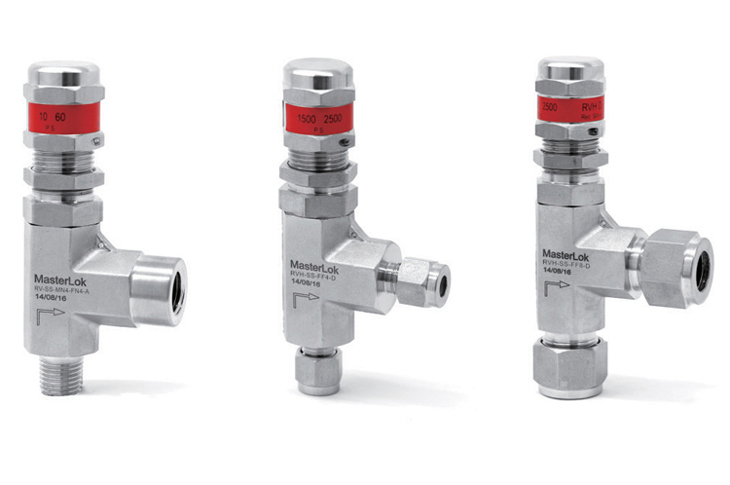

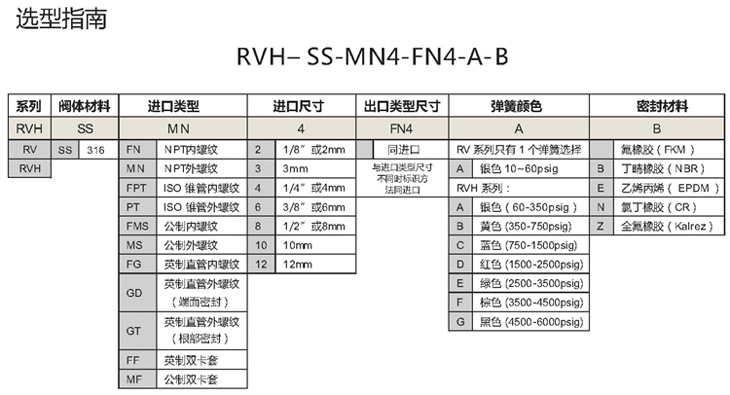

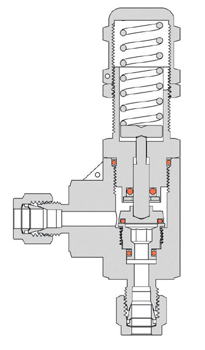

RVH Series RVH Series ■ For liquid or gas ■ set pressure: 7 springs are available, increasing the choice range of setting pressure, 3.4 to 414bar (50 to 6000psig) ■inner diameter: 3.6mm ■ balance stem design eliminates the influence of back pressure, set pressure. ■ working temperature: -23 to 148 DEG C (-10 DEG F to 300 DEG F) ■ adjustable valve cap, adjustable pressure setting ■ Anti - songsI hole can effectively maintain the set pressure preset ■ In a variety of seal materials available ■ In the label range of setting pressure ■ when the set pressure is lower than 1500psig can choose manual override Control handle, the handle can open the valve without changing the setting pressure ■ interface size: 1/4 to 1/2, 6 to 12 mm dual card sets 1/4 "to 1/2" thread |

RV Series RV Series■ For liquid or gas ■ set pressure: 10 to 60psig (0.68 to 3.9bar) ■ inner diameter: 4.0mm ■ D = preset pressure required pressure back pressure -0.8* ■ working temperature: -23 to 148 DEG C (-10 DEG F to 300 DEG F) ■ adjustable valve cap, adjustable pressure setting ■ Anti - songsI hole can effectively maintain the set pressure preset ■ In a variety of seal materials available ■ In the label range of opening pressure ■ when the set pressure is lower than 1500psig can choose manual override control handle This handle can open the valve without changing the setting pressure ■ interface size: 1/8 to 3mm, 1/2 to 12mm dual card sets 1/4 "to 1/2" thread |

|

Previous:

One way valve